In Australia, the garage has traditionally been a multifunctional space, serving not just as a shelter for cars but also as a storage area for a myriad of household items, tools, and occasionally, even as a workspace or recreational area. However, a common observation across many Australian homes is that garages tend to be particularly cluttered and messy. This phenomenon can be attributed to several factors, ranging from changing lifestyle patterns to architectural design and consumer behavior. This article delves into the reasons behind the messiness of Australian garages, shedding light on the underlying causes and potential solutions. It also introduces a range of solutions that can assist you to reclaim your garage.

Shifting Lifestyle Patterns

One of the primary reasons for cluttered garages is the evolving lifestyle of Australians. As people acquire more possessions, from sports equipment to seasonal decorations, the garage often becomes the go-to storage space. The rise of hobbies and home improvement projects has also contributed to the accumulation of tools and materials, often stored in the garage for convenience.

Lack of Adequate Storage Solutions

Many Australian homes, especially older ones, were not designed with sufficient built-in storage. As a result, garages become the overflow space for items that do not fit inside the house. Without proper organization systems such as shelving, cabinets, or racks, these items can quickly accumulate, creating clutter and disorganization.

The Consumer Culture

The surge in consumerism, driven by the ease of online shopping and the allure of sales, has led to an increase in household belongings. Many Australians find themselves purchasing items on impulse or in bulk, which, due to lack of immediate use or space inside the home, end up in the garage. This consumer habit exacerbates the issue of clutter, making garages appear messier than ever.

Multipurpose Use of Garage Space

Garages in Australia are increasingly being used for purposes other than parking cars. They serve as workshops, home gyms, and even entertainment areas. This multipurpose use, while beneficial, contributes to the clutter, as it introduces a variety of items into the space that are not always neatly organized or stored.

Procrastination and Lack of Time

The task of cleaning and organizing a garage can be daunting, especially when the clutter has been accumulating over time. Many individuals postpone this task due to its overwhelming nature or due to a busy lifestyle. This procrastination, combined with a lack of dedicated time to tackle the mess, results in garages remaining cluttered for extended periods.

Architectural Design and Planning

The design of some Australian homes does not prioritize garage storage efficiency. Garages are often designed to meet minimum size requirements for vehicles, with little consideration for storage or organization. This lack of foresight in design contributes to the challenge of keeping garages tidy and well-organized.

Seasonal and Infrequently Used Items

Garages often house seasonal items such as holiday decorations, winter clothing, and sports equipment, which are not used year-round. These items take up valuable space and contribute to the clutter, especially when not stored properly.

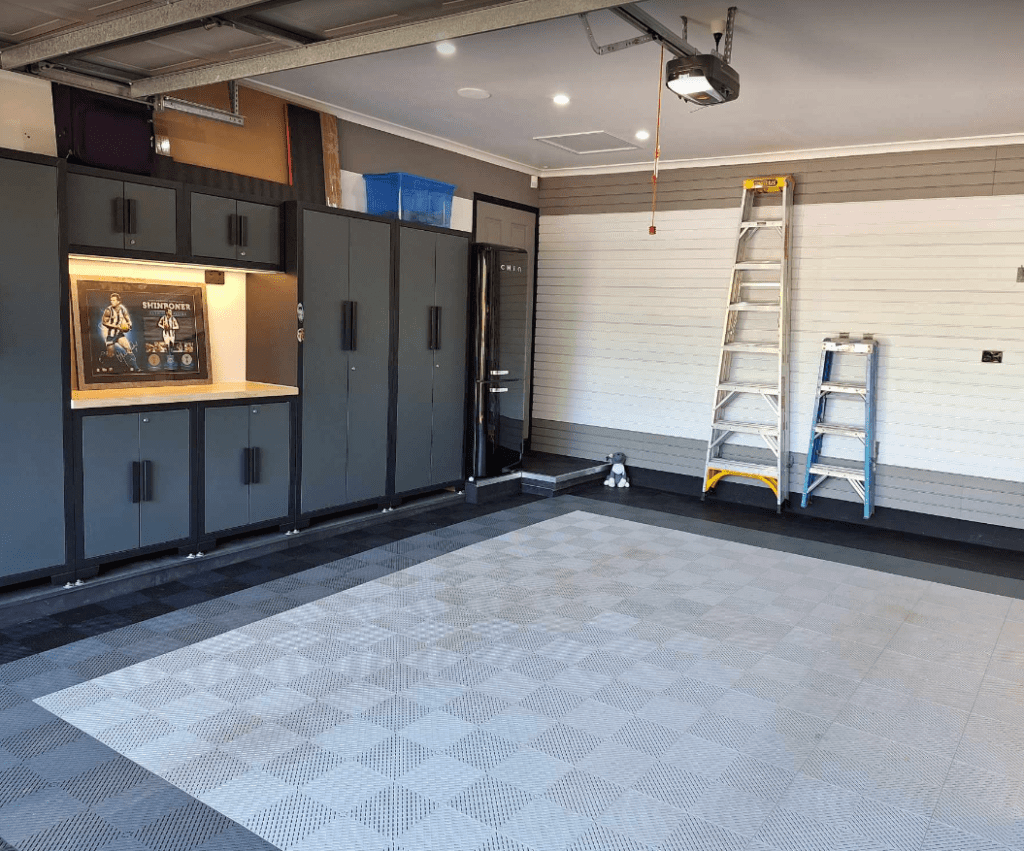

Reclaim Your Garage – Solutions and Strategies

Addressing the messiness of garages requires a multifaceted approach. You can adopt various strategies to mitigate this issue so you can reclaim your garage:

- Implementing Efficient Storage Solutions: Installing shelving, cabinets, and overhead storage can maximize space and reduce clutter.

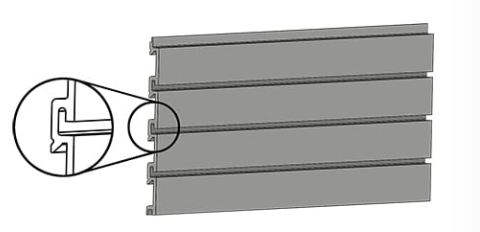

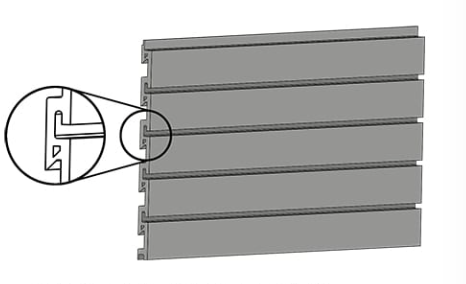

- Utilise your walls: Wall storage solutions allow you to maximise the height and width of your walls as storage areas. Garage wall storage solutions enable the use of hooks, baskets, and shelves to safely store everything from sporting goods to power tools and even work boots.

- Regular Decluttering: Setting aside time to sort through items and dispose of or donate those that are no longer needed can significantly reduce clutter.

- Designating Spaces: Assigning specific areas within the garage for different types of items can help maintain organization.

- Investing in Multipurpose Furniture: For garages used as multipurpose spaces, furniture that offers storage can be particularly useful.

- Embracing Minimalism: Adopting a more minimalist approach to possessions can prevent the garage from becoming a catch-all storage space.

In conclusion, the cluttered state of Australian garages is a multifaceted issue influenced by lifestyle changes, architectural design, and consumer habits, among other factors. By acknowledging these causes and implementing practical solutions, you can reclaim your garage, transforming it into an organised, and functional space.