This week, I received an inquiry about installing StoreWALL on a polystyrene block wall. Since I wasn’t very familiar with this building material, I took the time to explore the process in detail with the customer. Here’s what I learned and the solutions we discussed.

What Are Polystyrene Blocks and Why Are They Popular?

Polystyrene blocks are becoming a go-to material in modern construction for their blend of energy efficiency, light weight, and cost-effectiveness. These blocks are known for their superior insulation, which helps maintain consistent indoor temperatures, leading to reduced heating and cooling costs. Their lightweight nature makes them easy to handle and install, speeding up construction and reducing labor costs. Additionally, polystyrene blocks are moisture-resistant and durable, making them suitable for a variety of climates. They are also recyclable, making them an environmentally friendly choice for sustainable building projects. As energy-efficient and budget-conscious housing solutions continue to gain momentum, polystyrene blocks are emerging as a preferred option for builders.

How Are Polystyrene Block Walls Constructed?

Polystyrene block walls are assembled in a straightforward process, similar to stacking LEGO blocks. These blocks are cut to size and feature a hollow core, which is later filled with concrete, and reinforced with steel, forming a strong, dense wall structure. The polystyrene on the outside remains intact, providing insulation on both sides of the concrete core. This combination of materials creates a highly efficient and durable wall system.

Installing StoreWALL on Polystyrene Block Wall: The Challenges

When installing StoreWALL on a polystyrene block wall, the main challenge is finding a way to securely fasten the installstrips to the polystyrene while ensuring they can support the weight of whatever will be stored. I suggested two possible solutions to the customer:

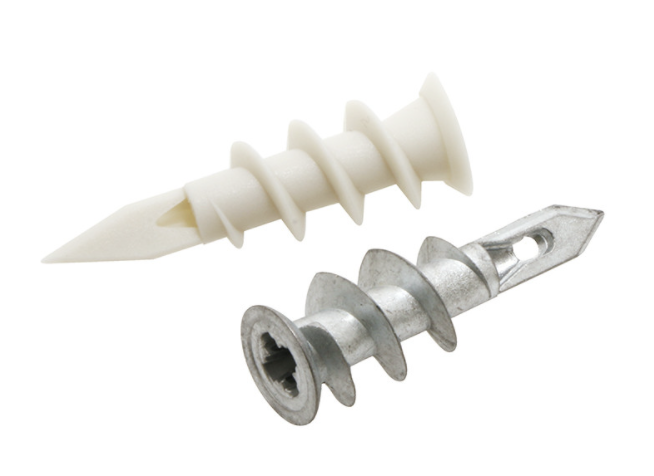

Plasterboard Zinc Anchors

One option is to use plasterboard anchors, which can be placed behind each of the 12 screw holes on the StoreWALL installstrip. Each anchor can support up to 10kg of weight, making it a reliable and efficient method. This approach is also relatively quick and straightforward, using proven fasteners that are easy to source and install.

Nail Anchors

The second option involves using nail anchors long enough to penetrate into the concrete core behind the polystyrene. To determine the correct length of the fastener, you’d first need to puncture the block to measure the thickness of the polystyrene. The fastener should extend at least 20mm into the concrete for optimal hold. While this method provides a stronger, more secure solution, it may require longer and thicker anchors, such as 75mm or even 100mm options. These are readily available and should provide ample support when fastened into the concrete.

Both methods offer viable solutions depending on the specific needs of the installation, with the nail anchors providing a more robust option for heavier loads.